Transformation: Baumert & Dabergotz receives "Digital Jetzt" funding for Cobot

The metal processing company Baumert & Dabergotz GmbH has been a traditional company since 1926 and manufactures individual solutions in the field of radiator technology, tank and container construction. The company mainly produces fuel and hydraulic tanks for large vehicles and mobile cranes. It also repairs radiators and fuel tanks and manufactures pipe segments for temperature control technology to customer specifications in its own production facility. The regional company currently employs 14 people and will be taking on a new apprentice from August 1, 2024.

Hanover Region

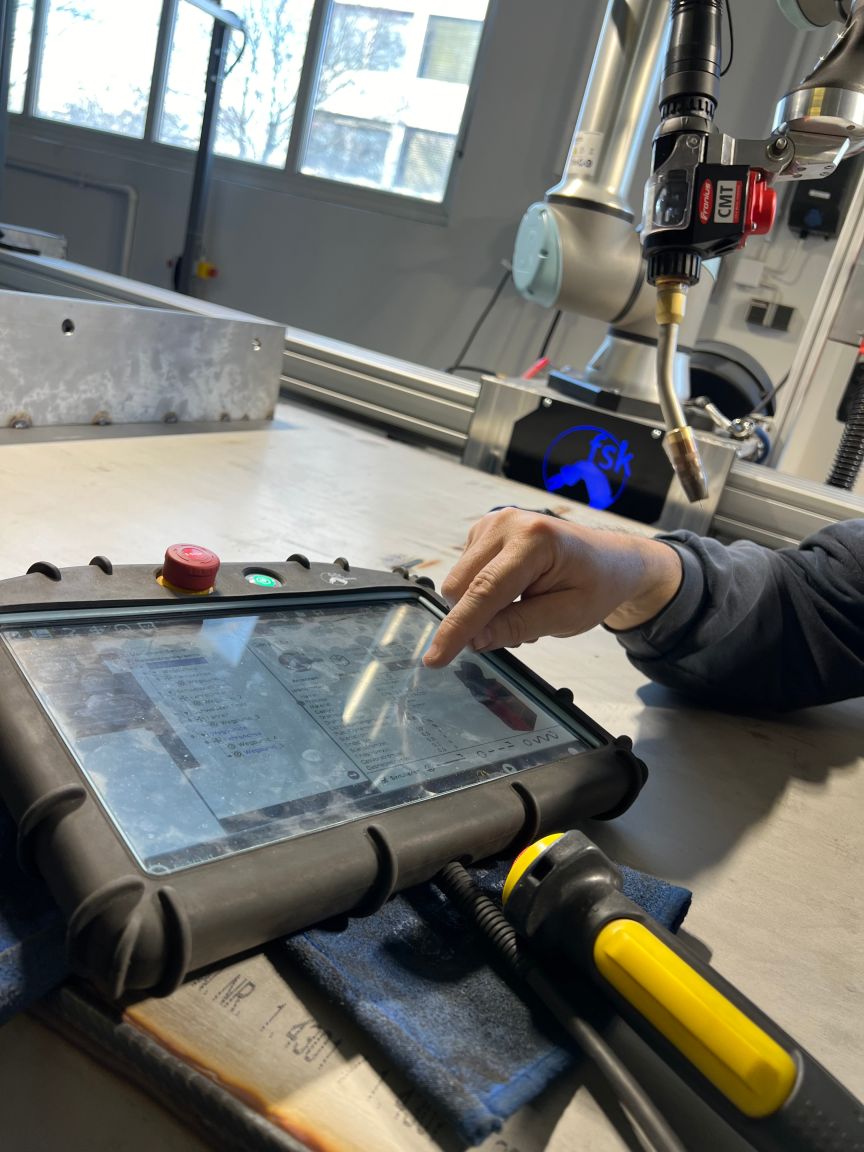

Hanover RegionThe company Baumert & Dabergotz has received €50,000 in funding for digitalization processes from the federal funding programme "Digital jetzt". The Hannover Region Economic Development Agency provided the company with intensive support during the application process, andBaumert & Dabergotz GmbH used the funding to finance a cobot from Universal Robots, which is currently the largest welding cobot on the market with a welded seam measuring 7 meters in length.

The new cobot is not a replacement for personnel, but speeds up the company's production because other work can now be carried out in parallel with the welding process. The robot can also work more precisely and delivers high quality. Welding with the Cobot means that every production part looks exactly the same. The machine can be programmed quickly, making it easy to train employees to use the cobot. The machine is in daily use and is programmed at the simple touch of a button by the operator.

Digitalization, progress and further development. As a next step, the company is aiming to introduce an AI-supported ERP system. In addition, articles can be digitally categorized by further developing the process. Those responsible at Baumert & Dabergotz GmbH are also planning to introduce an online portal for production monitoring and an automated ordering process. This will allow customers to track the production status of the ordered product at any time. A small number of high-quality items are produced in the production department. Baumert & Dabergotz GmbH therefore focuses on the individuality and uniqueness of products through customization.

Contact us

Kai Weber

Hanover Region

Economic Development

Department of Economic Development and Employment Promotion