Positive mid-term review of the 3D printing experimental laboratory

3D printing consortium

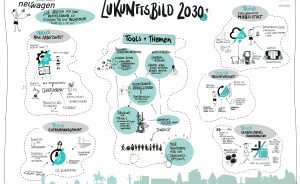

3D printing consortium The 3D printing consortium Hannover , a merger of the three companies dreiConsulting | Additive Manufacturing Germany GmbH & Co KG , LikeAbird and Formwerk3D , began implementing the 3D printing experimental laboratory supported by the Hannover Region Economic Development Corporation in April 2020. The aim of the measure is to raise awareness among regional companies of the potential applications of additive manufacturing in order to realize new or more sustainable products and production processes.

Although the measures against the spread of the coronavirus have naturally also affected the work of the consortium, the partners were able to implement four demonstrator projects halfway through the planned project period. In addition, the implementation of a digital 3D printing meetup and cooperation with partners such as " nachhaltig.digital ", " Niedersachsen Aviation " or the " Digitalagentur Niedersachsen " have enabled the sensitization of around 40 companies to date.

The consortium has also initiated cooperation with regional research institutes such as the IPH - Institut für Integrierte Produktion gGmbH , the Institute for Bioplastics and Biocomposites (IfBB) , the Institute for Plastics and Recycling Technology (IKK) and the Institute for Product Development and Equipment Engineering (IPeG) . All of these activities have also led to further projects with a total volume of € 1.15 million being applied for or approved in Hanoverian institutes and companies.

The consortium's demonstrator projects to date cover various sectors and topics. In the first project, the consortium's engineers designed adapters that enabled clinics in Hanover and Hildesheim to connect existing filters with available protective masks. This made it possible to quickly implement effective virus protection independently of the highly sought-after protective masks on the global market.

Crafting Future GmbH used the consortium's expertise to develop ecologically optimized bento boxes and bring them to prototype status. In this project, the CO2 footprint of the food boxes was minimized through the use of bio-based plastics and targeted material savings. In its project, the bicycle store RadConcept sought an alternative to the tedious procurement of bicycle spare parts. The solution is the programming of a configurator with which the company can now print customer-specific brackets, e.g. for reflectors, in its own store. The consortium designed innovative housings for X-ray sources and units for FineTec Fine Focus Technologies GmbH.

© 3D Printing Consortium

© 3D Printing Consortium The construction of the new 3D printing experimental laboratory in Lindener Hafen is also progressing. The building, including the laboratory equipment, should be available to interested companies by early summer 2021. Until then, the members of the 3D printing experimental laboratory will continue to support interested companies with the existing infrastructure. For example, another project related to veterinary medicine will be starting soon. The second digital 3D printing meetup is planned for March 2021.

Contact us

Dr. Michael Merwart

Hanover Region

Economic Development

Department of Economic Development and Employment Promotion

3D printing consortium

3D printing consortium 3D printing consortium

3D printing consortium © 3D printing consortium

© 3D printing consortium 3D printing consortium

3D printing consortium 3D printing consortium

3D printing consortium © 3D printing consortium

© 3D printing consortium © 3D printing consortium

© 3D printing consortium © 3D printing consortium

© 3D printing consortium 3D printing consortium

3D printing consortium 3D printing consortium

3D printing consortium 3D printing consortium

3D printing consortium © 3D Printing Consortium

© 3D Printing Consortium © 3D printing consortium

© 3D printing consortium